The advantages to digitally printed labels

Today’s choices of print methods are growing! Never before have the possibilities of what can be created using technology been so vast. With designs becoming increasingly complex, changing standard labels into marketing tools and creating solutions has never been this achievable.

Why is digital technology leading the way compared to traditional printing methods?

When manufacturing a product label, it’s important to think ahead and prepare for our customer’s requests, both in the immediate and longer term. The technology we use and having the right tools plays a huge part in what we can offer. Technology also allows us to be more cost efficient and flexible without compromising on quality.

How is digital print more cost effective?

Unlike traditional printing methods, digitally printed labels don’t require plates, which means no tooling fees. Generally, the technology is cheaper to run, and because of the flexibility, printing a different design is as simple as pressing a button. Imagine being able to print what you need, when you need it and combine multiple orders into a single run. No breaks, no plate changes, no downtime, so no additional costs and our savings are passed onto our customers.

When digital print is paired with embellishments, the added value is limitless. Premium products need high-end quality labelling, and a high-definition press is the best way to deliver that x-factor.

What are the main differences between

digitally printed labels and traditional flexographic label printing?

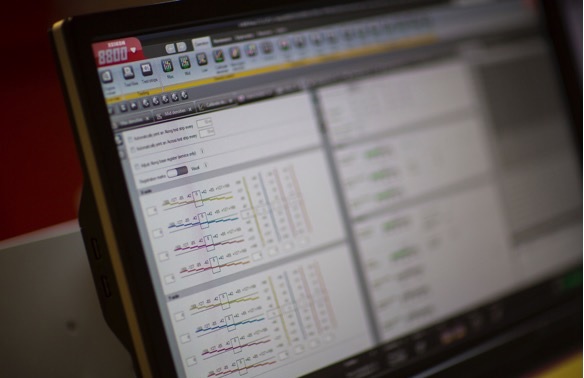

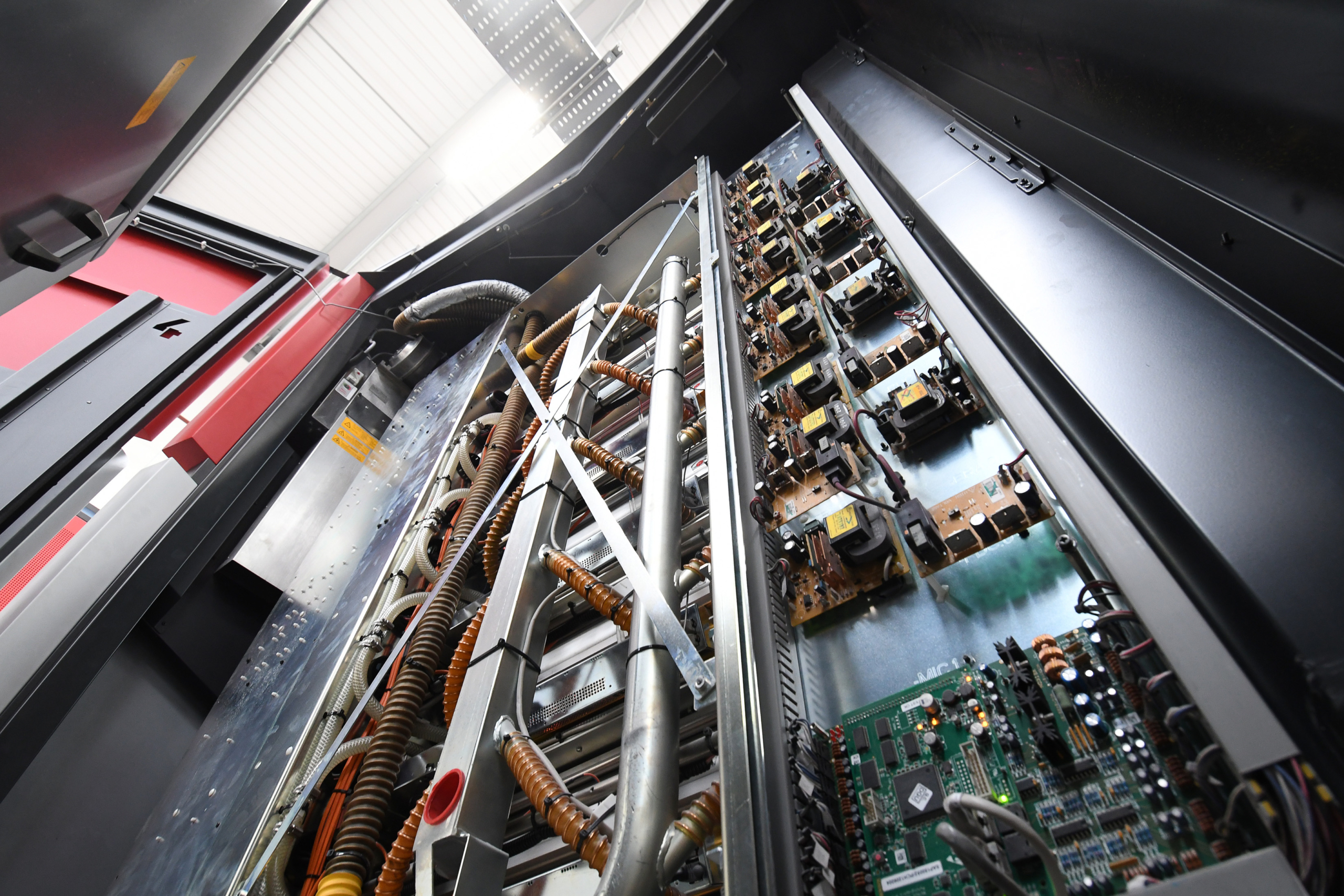

Digital printing differs radically from traditional, flexographic technology. The most obvious difference is that it doesn’t require printing plates to initiate a job. All it takes is a computer, high-resolution artwork and a label can be printed. Of course, there are complexities depending on the design, but assuming everything is as it needs to be, it can be a straight forward process.

Unlike digital label printing, flexographic printing transfers ink onto the material using flexographic plates mounted on printing cylinders. These plates are sheets of polymer material. Multiple plates are required and each plate will hold information on a specific colour which can compromise on quality as colour can spill between plates. There are challenges which can vary which can also affect pressure, creating inconsistencies. If a design changes, the plates need changing and it can become costly.

Digital presses function more like printers. Instead of plates, they develop images internally by transferring toner onto the substrate which is then fused. This means that every single print can be executed in high-definition!

When are digitally printed labels the best option?

Every time!!! Digital can deliver regardless of design. For colours, consistency and quality, digital has the advantage. You can pair digital print with an array of finishes or embellishments.

Not sure how to transform your design into an eye-catching label? Speak to one of our team. We’re experienced in transforming artwork into a label solution.